Krafft and AssociatesYour choice for specialty grinding solutions

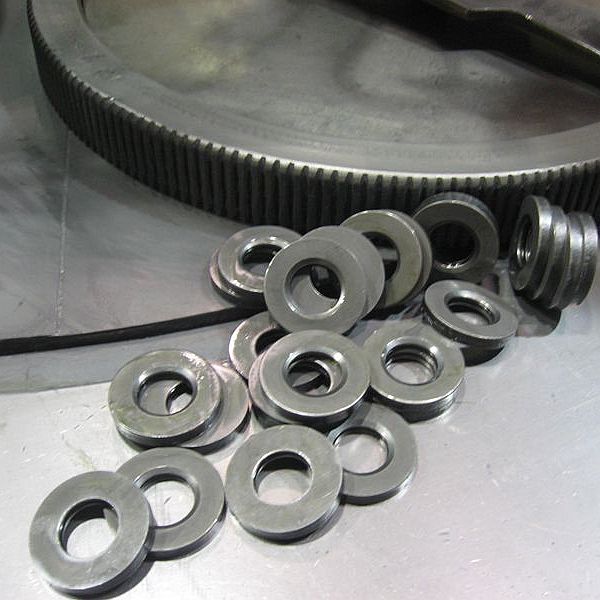

Lapping

Lapping is the best known machining process that produces precise flatness, thickness, and a better finish. We offer single sided, double sided, gray, and diamond lapping services. Metal working, tool rooms, optics, wire drawing, petrochemicals, laboratory, aerospace, marine, etc. are a few areas that make use of lapping processes extensively.

Precision and Quality

We pay attention to the details.